INQUIRY

Capacity:180t/h~240t/h

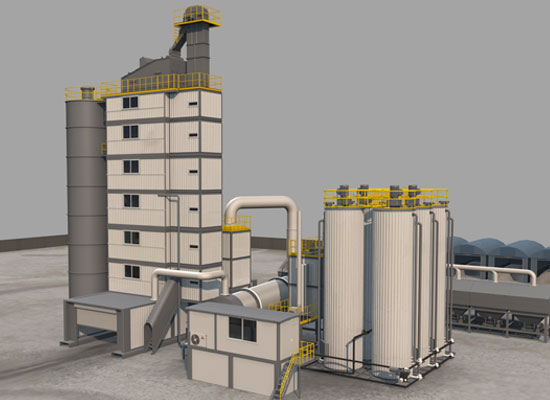

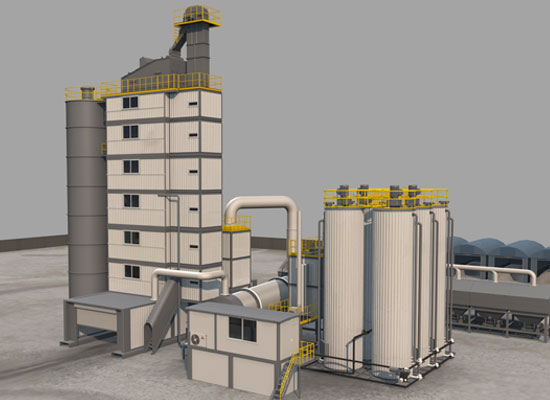

Features of CLB Containerised Asphalt Mixing Plant

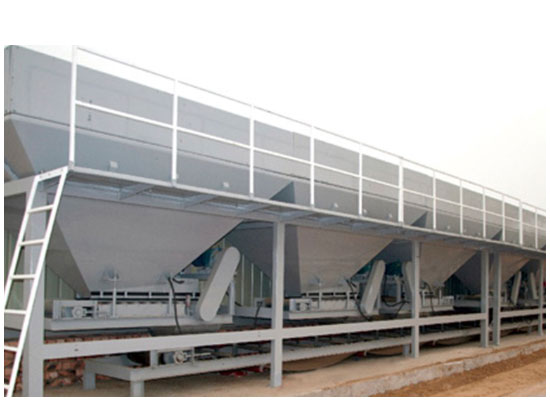

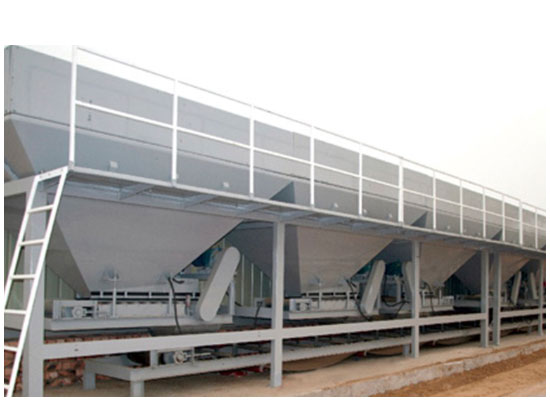

1.This equipment adopts an integrated overall design. The whole is a container-type structure, which is extremely convenient for transportation and installation. The overall structure is compact and the floor space is small.

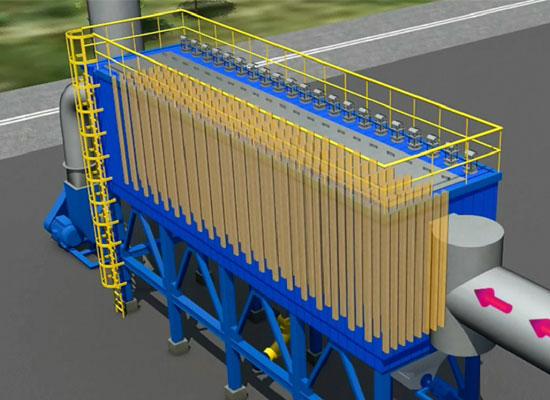

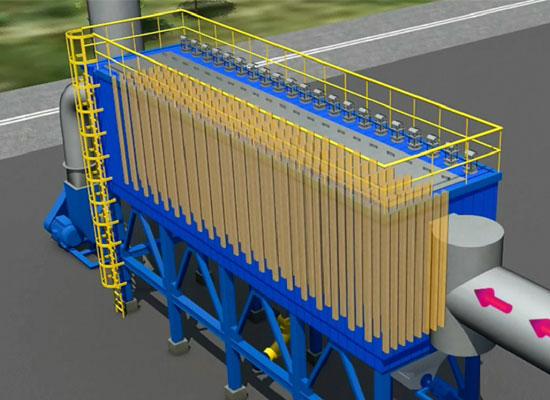

2.This equipment adopts system process environmental protection optimization design.Equipped with advanced environmental protection devices from the cold collecting hopper to the finished product discharge tank.Ensure that dust and asphalt fume are sucked in and discharged in time and processed centrally.

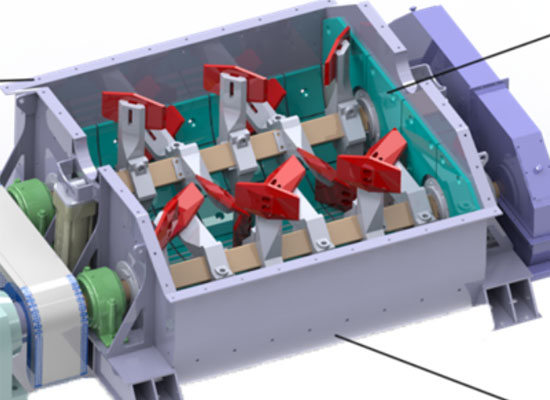

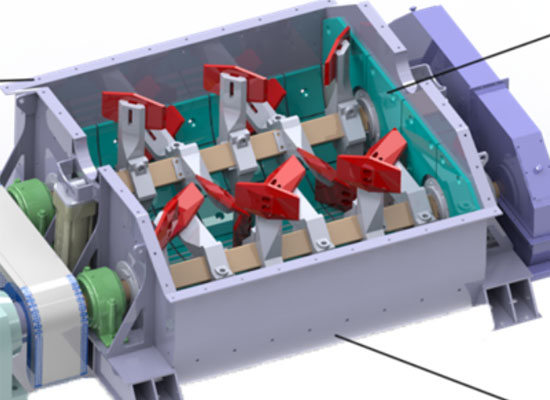

3.This equipment runs stably and has a high output (Ōēź300T / h). The three components are of reliable quality, and the shaker, mixing tank (400,000 T material for blades), and 2 million T material for drying drum are guaranteed.

4.The overall design of this device is compact and macro. The work system is well-coordinated and arranged with good visual effects.

It Adopts four sets of famous powerful direct-connected gear motors to drive the drying drum. Well calculated and carefully heat treated drying drum, world class bearings have long service life and stable performance.

Sinoroader | Asphalt Burner

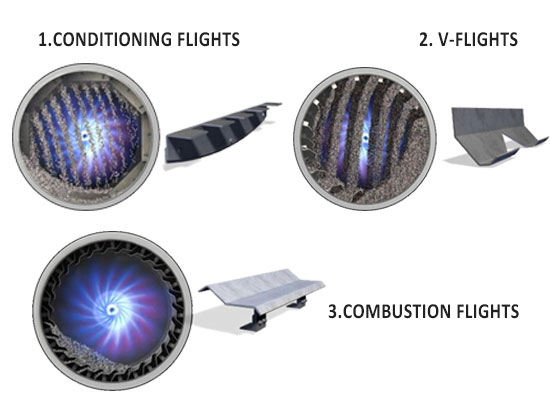

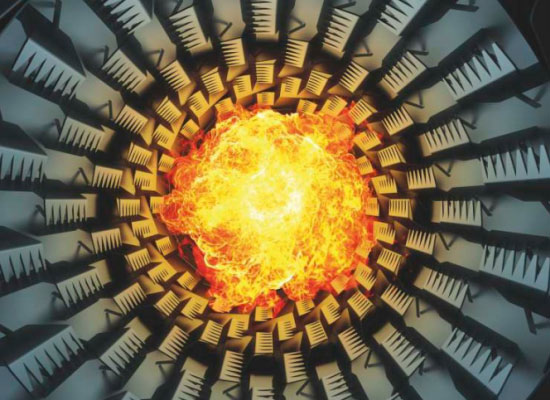

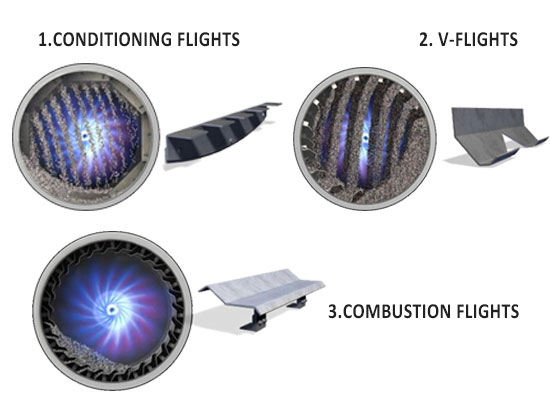

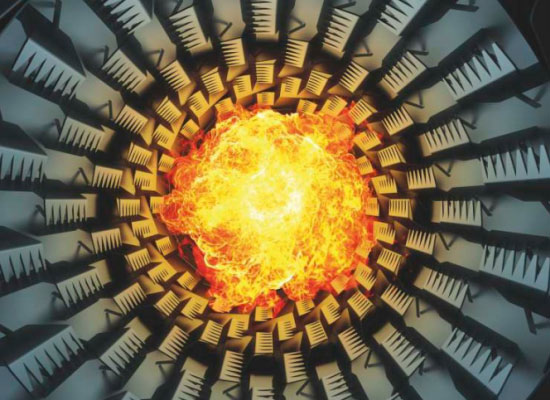

The Sinoroader burner uses advanced technology to burn sufficiently and cleanly. Sinoroader Burner provides the best performance and efficiency. The performance and delivery will be guaranteed by pre-testing and wiring. ItŌĆÖs available in varieties of fuel firing combinations.

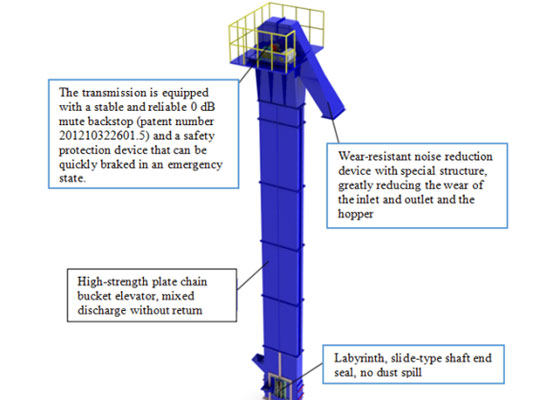

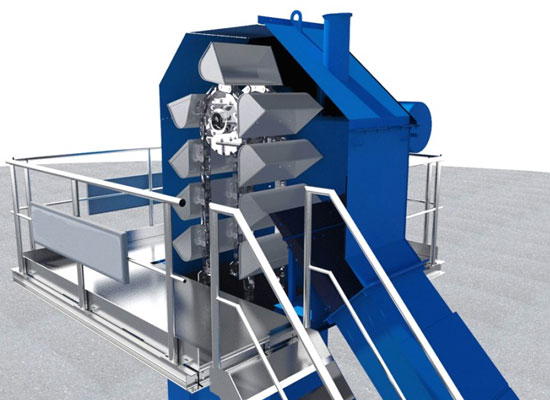

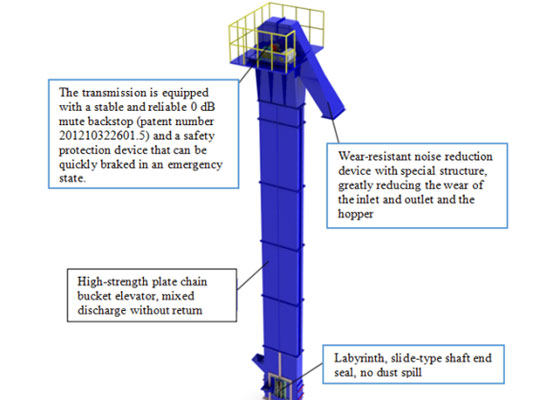

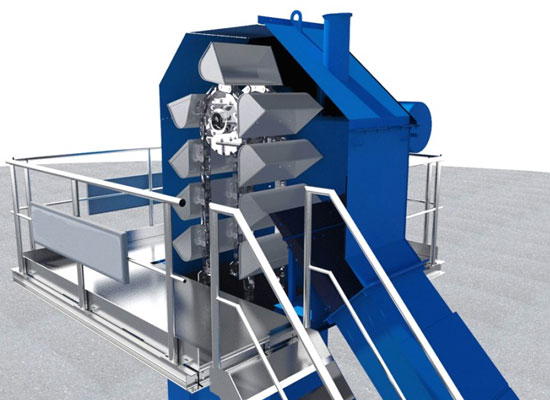

Sinoroader | Hot Elevator

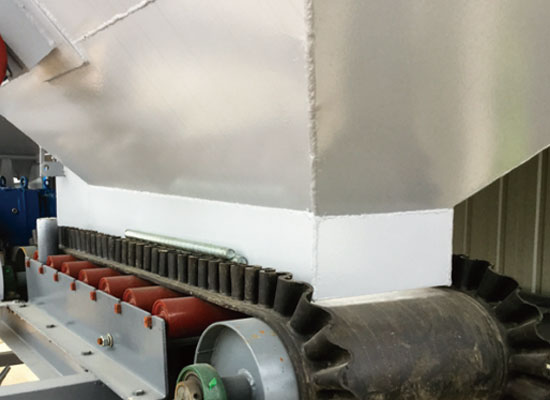

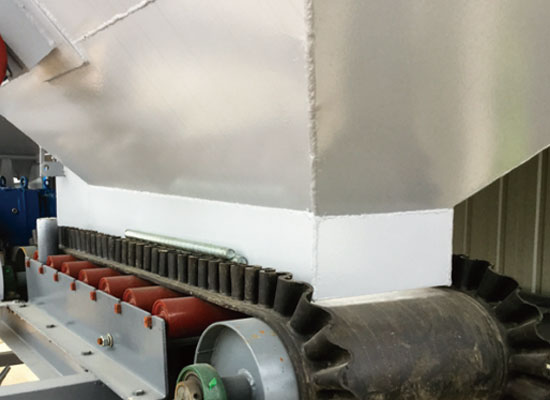

The hot elevator is used for feeding dry aggregate to screens.The housing is fully-enclosed and dust-proof, which can protect the integrity of the dried aggregate. The steel buckets with reinforced edge are set to convey the aggregate.The chain of it is wear-resistant, so it can prolong service life. Meanwhile, the split sprockets can reduce the time and effort spent on maintenance.

| Model | CLB2000 | CLB2500 | CLB3000 | |

| Capacity | 180t/h | 200t/h | 240t/h | |

| Cold silo | Quantity* volume | 5*10m┬│ | 5*10m┬│ | 5*18m┬│ |

| diameter | 2.2m | 2.2m | 2.5m | |

| length | 9m | 9m | 9m | |

| fuel | Diesel, heavy oil, natural gas | |||

| Drying capacity (temperature rise 140Ōäā) |

LB1500 Asphalt Mixing Plant’╝īMobile Asphalt Mixing Plant, Drum Mix Asphalt Plant,Continuous Asphalt Mixing Plant,Asphalt Hot Mix Plant. |

|||

| Water content 3% | 220t/h | 220t/h | 300t/h | |

| Water content 5% | 180t/h | 180t/h | 240t/h | |

| Dust Collector | Primary Gravity Dust Collector + Baghouse Dust Collector | |||

| Mixing Tower | screen layers | 5 | 5 | 5 |

| Screening area | 24.2m┬▓ | 28.1m┬▓ | 28.1m┬▓ | |

| Hot storage bin | 5+1 | 5+1 | 5+1 | |

| Hot storage bin volume | 21m┬│ | 40m┬│ | 40m┬│ | |

| Aggregate scale | 2000kg | 2500kg | 3000kg | |

| Powder scale | 200kg | 300kg | 400kg | |

| Asphalt scale | 200kg | 300kg | 400kg | |

| Mixing power | 2*37kw | 2*45kw | 2*45kw | |

| Mixer capacity | 2000kg | 3000kg | 3000kg | |

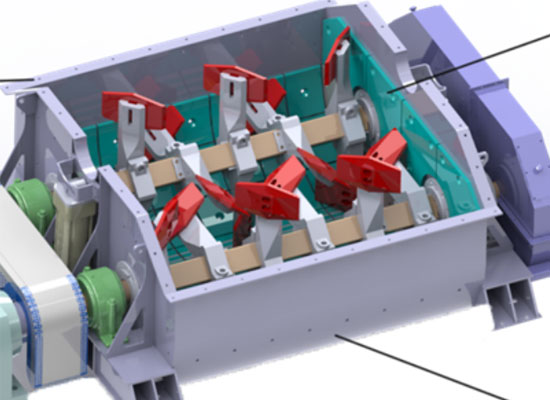

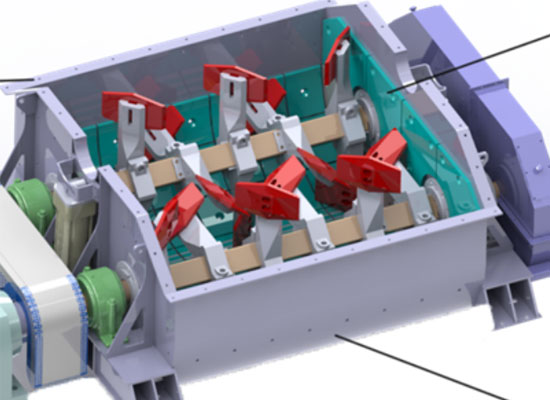

| Mixing type | Double horizontal shaft, double motor, synchronous reduction gear | |||

| Bitumen Supply System | Heated by heat transfer oil, 35,000 liters or 50,000 liters of horizontal or vertical asphalt tanks, according to customer requirements | |||

| Filler Supply System | Standard: (recycled powder + extra powder) | |||

| Hot Mix Storage Silo | Side-mounted, bottom-mounted finished silo | |||

| Optional cold regeneration | Add recycled material directly to the mixer | |||

| Optional thermal regeneration | regeneration | Double drum | ||

| Control System | Fully Automatic Computer Control(IPC+PLC+MONITOR+LASER PRINTER+AIR CONDITIONER) | |||

| Environmental standards | Smoke dustŌēż20mg/Nm┬│ | |||

| Production standards | Industry standard / national standard / CE standard, the highest standards of implementation | |||

Q How to understand the accuracy value of the measuring system of the mixing station is accurate to 0.1%?

Q Do you provide overseas erection and training service?

Q What kind of dust collection system is used in the asphalt mixing plant?

Q Is the equipment control system fully intelligent?

Q What kind of dust collection system is used in the asphalt mixing plant?

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China