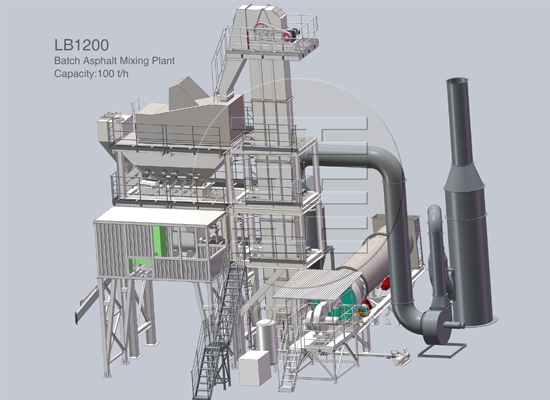

Asphalt batch mix plants are the most widely used type of asphalt plants. Batch mix means there is a time interval between two mixing batches. Usually, batch cycle is 40 to 45s.Asphalt batch mix plants produce high quality asphalt mixture for all grades of road pavement /rehabilitation and all sizes of asphalt production. Furthermore, they can be tailored as clients special requirements.

SINOSUN Machinery manufactures several types of asphalt batch mix plants with capacity from 40-400t/h, including classic type--LB series, mobile type--YLB series, energy efficiency type--CLB series, premium type--RAP series, compact type (no mixing tower)--D series.

“WHY DO SO MANY PROFESSIONALS

CHOOSE SINOSUN?”

WhatsApp:

+86 18224529750

Longxiang Industrial Park ,

Weidu District, XuChang,HeNan, China