What are the hazards of dust generated by asphalt mixing plant? How to deal with it effectively?

January 28th, 2022

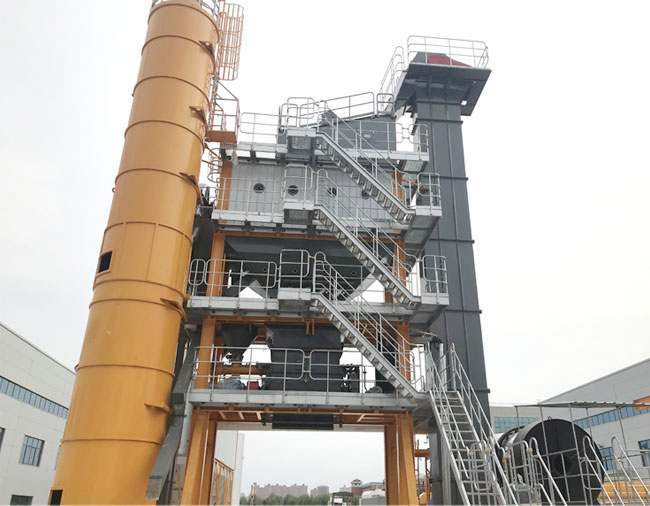

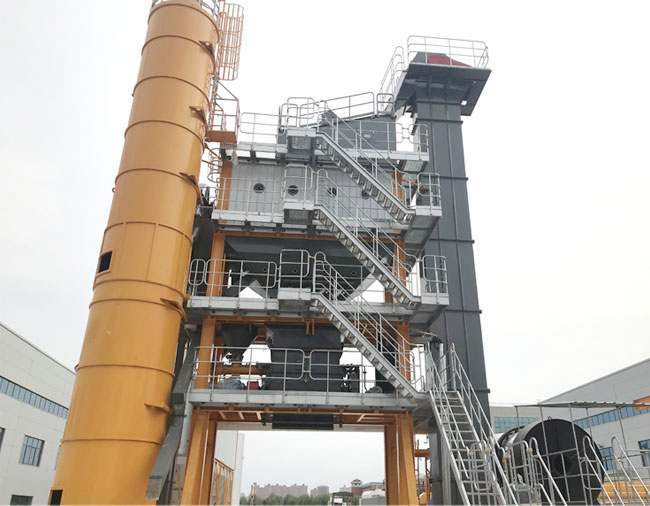

Asphalt concrete mixing plant is the place where asphalt concrete mixture is produced. The main process is: heat the raw stone, raw asphalt, raw stone powder and additives to a certain temperature according to the requirements of pavement design specifications, and then add them into the mixer after measuring the weight respectively to mix them into asphalt concrete mixture for use.

In this process, raw materials need to go through transportation, transmission, mixing, heating, mixing and other links to produce a large amount of dust. Due to the special properties of asphalt concrete mixture production, these dust are small dust particles, which will cause a certain amount of pollution to the surrounding air.

The large-scale asphalt mixing station itself has a large production volume, which consumes a lot of stone raw materials and asphalt raw materials. Every day, a large number of materials and finished products transportation vehicles will bring no small dust to the asphalt mixing plant area.

In addition, a large amount of dust will also cause early damage to the mechanical equipment itself. Because the dust particles generated during the operation of the asphalt mixing plant are very small, it is easy to enter the interior of the mechanical equipment.

So how should we effectively deal with the dust produced by asphalt mixing plant?

(1) Improved mechanical equipment

Asphalt mixing plant equipment is a major producer of dust, so to reduce the amount of dust, we must start with improving asphalt mixing equipment. Through the improvement of the whole machine design, optimize the design accuracy of each sealing part of the machine, strive to realize the full sealing of the asphalt mixing process, and control the dust within the mixing equipment to reduce the overflow of dust.

In addition, to optimize the operation program design of mixing equipment, we should pay attention to the control of dust overflow in every link of machine operation, so as to achieve efficient dust control during the operation of the whole machine. Finally, in the practical application of mixing equipment, we should constantly update the process and actively use high-tech technology to keep the machine itself under the best machine condition, so as to control the pollution of dust overflow to the greatest extent.

(2) Wind dust removal

Wind dust removal is an old-fashioned dust removal method. This method is to use cyclone dust remover for dust removal. Because this old-fashioned dust remover can only remove dust with large particles, but can not remove dust with small particles, the old-fashioned wind dust removal effect is not very excellent, and some particles with small diameter are still discharged into the atmosphere, It has caused pollution to the surrounding environment and can not fully meet the dust treatment.

Therefore, the design of today's wind dust collector is also constantly improved. Through the combination of multiple sets of cyclone dust collectors of different sizes, it can complete the screening and removal of particles of various sizes, and the absorption and removal of dust with smaller particles, so as to achieve the purpose of protecting the environment.

(3) Wet dedusting

Wet dust removal is aimed at wind dust removal. The working principle of wet dust collector is to use the adhesion of water to dust for dust removal.

However, wet dust removal has a high degree of dust treatment, which can effectively remove the dust in the mixing process. However, water pollution is caused because water is used as the raw material of dust removal. In addition, some construction areas do not have much water resources for dust removal. If wet dust removal method is used, water resources need to be transported from a distance, which increases the production cost. On the whole, wet dust removal can not fully meet the requirements of society.

(4) Bag dust removal

Bag dust removal is a more suitable dust removal mode in asphalt mixing. Bag dust removal is a dry dust removal mode, which is suitable for dust removal with small particles and is very suitable for dust removal in asphalt mixing.

The bag dust removal device uses the filtering function of the filter cloth to filter the gas. The dust with larger particles is precipitated by the action of gravity, while the dust with smaller particles is filtered out when passing through the filter cloth, so as to achieve the purpose of filtering the gas. Bag dust removal is very suitable for removing dust in the process of asphalt mixing.

First of all, bag dust removal does not need to waste water resources and will not cause secondary pollution. Secondly, the dust removal effect of bag dust removal is better, which is much better than that of wind dust removal. Then, bag dust removal can also collect dust in the air. When it is accumulated to a certain extent, it can be recycled.

In order to prevent damage to the surrounding environment, we should reduce the dust phenomenon in the process of asphalt mixing, recycle and reuse the dust, and realize scientific production and green ecological development.

January 28th, 2022

January 28th, 2022